Special feature of 1905 film network "People don’t make me, I’m not a prisoner. If someone attacks me, I will fight him. I will fight as long as he wants, and I will fight all the time! "

With the wonderful play of one enemy and one hundred enemies, it was launched on New Year’s Eve, which also officially opened the curtain of the 2023 online movie Spring Festival.

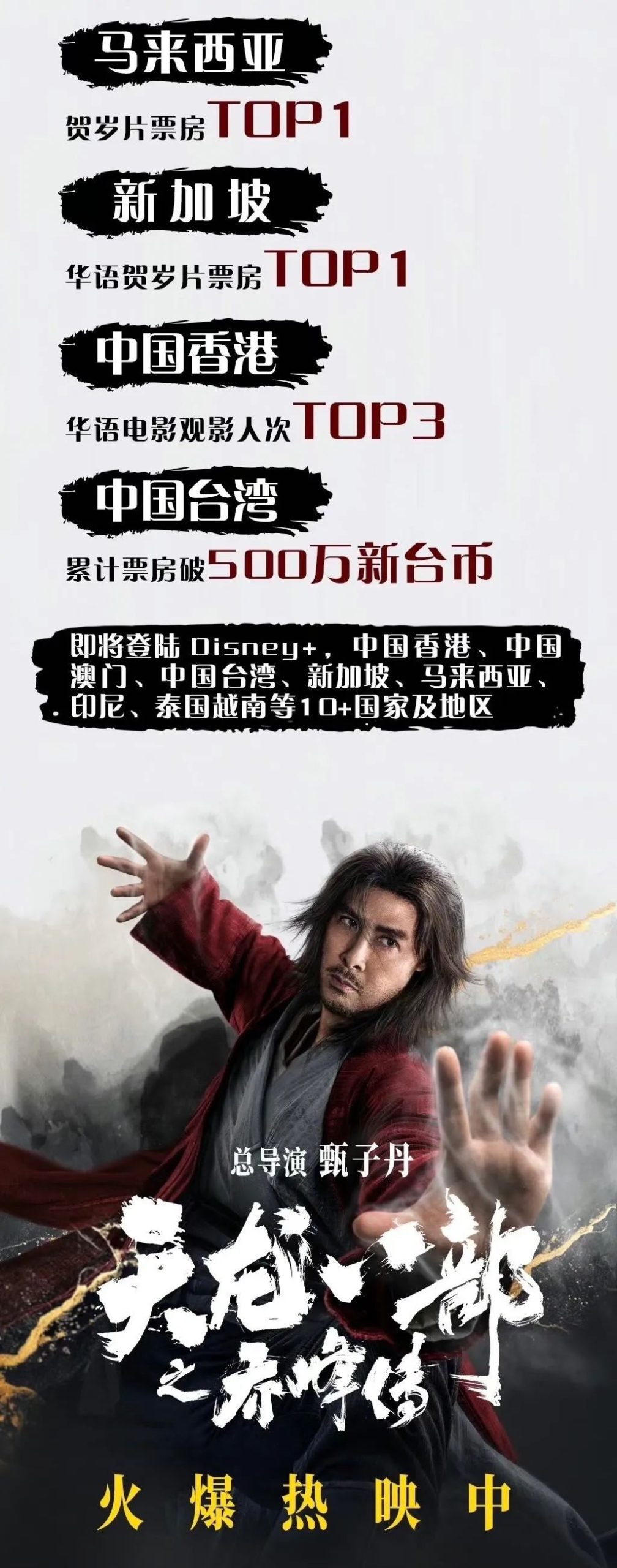

According to incomplete statistics, from Lunar New Year’s Eve to Lunar New Year’s Eve, the number of online movies in the Spring Festival file is 8, covering martial arts, action, comedy, love, family and other types of themes, meeting the different viewing needs of the audience.

At the same time, this year’s online Spring Festival file is also a gathering of stars, with strong strength behind the scenes:

For example, The Biography of Dragon in Qiao Feng is directed by Donnie Yen, supervised by Donnie Yen, starring Donnie Yen,,, with special performance and special guest starring.

The four directors who have been created separately jointly launched by,,,,, and so on.

Nowadays, the online movie Spring Festival file has entered the third juncture. In the general direction of improving quality and reducing quantity, what is the performance of this Spring Festival file?

Box office and word of mouth have risen together.

Comparing 20 films in 2021 with 14 films in 2022, the number of new films in the Spring Festival online movies this year is the least in three years. Although the number is small, the proportion of films with high box office is increasing, and the quality is also developing towards quality.

Qiao Feng Biography of Dragon and Eight Branches, Looking Up to See Happiness, Northeast Farewell to the Celestial Regiment 2, King of Sniper: Assassination, Happy Event … …In particular, from the 27th of the twelfth lunar month, the online Spring Festival file was opened with the animated film "The Shadow of the Westbound Journey", and the cinema comedy was launched on the fourth day of the Lunar New Year.Desperate husband, which constitutes a more complete and rich selection of Spring Festival films and expands the content supply within the schedule.

Qiao Feng Biography is undoubtedly the "leader" of this year’s online movie Spring Festival file, and its theme, production volume and lineup all belong to the blockbuster level.

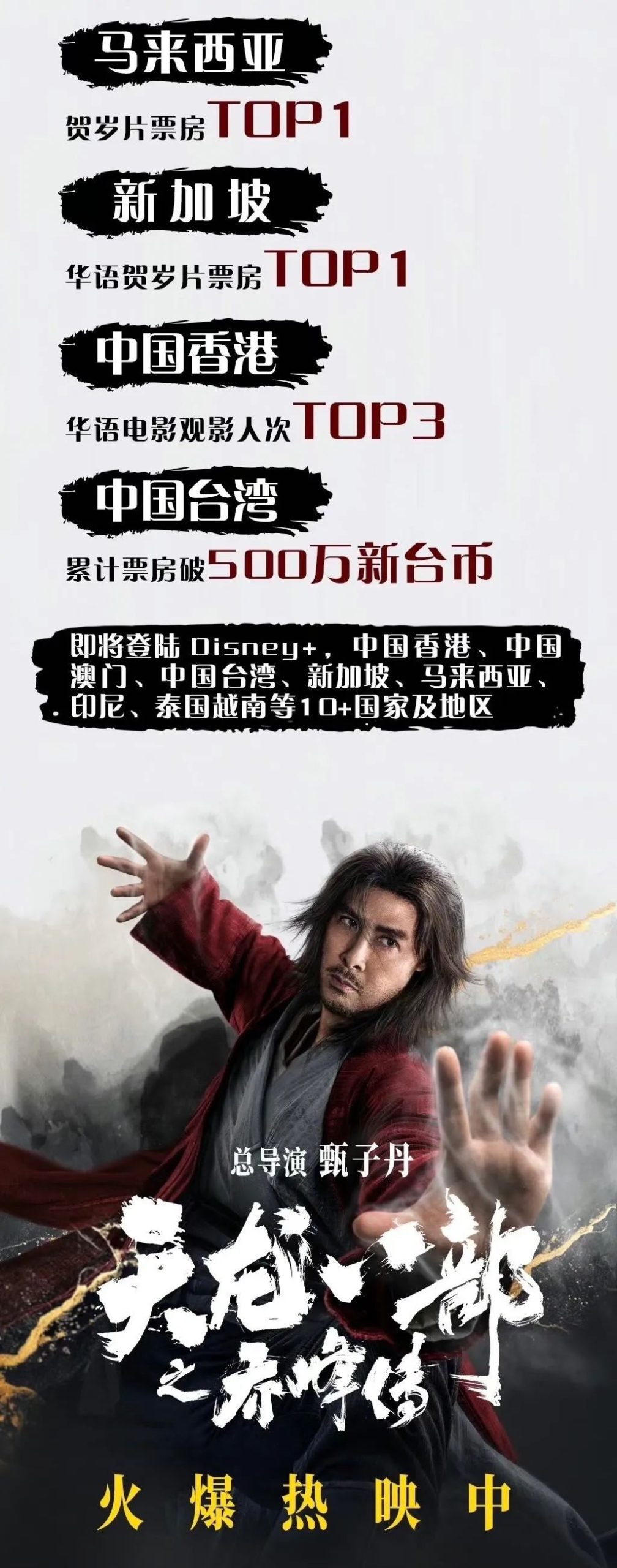

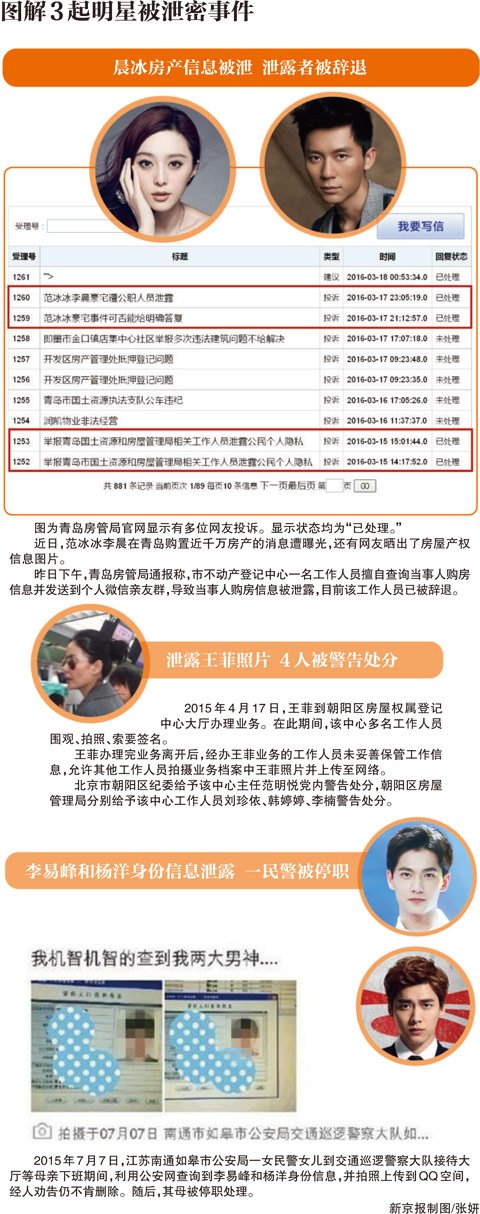

After the film was broadcast on the three platforms, it won the TOP1 of the three-platform single-chip paid online movie list for many days. The film not only has a prominent box office situation, but also continues to exert its strength during the New Year by virtue of its favorable reputation. The overseas website IMDb scored 6.8, and at the same time it was ranked as the TOP3 in the number of Chinese movie goers in China and Hongkong, with a good reputation and popularity.

According to an interview with Zhu Weijie, the chief producer, the film has also rushed out of the country and landed in overseas cinemas. At present, it has won the box office champion of Malaysian New Year’s film and the first box office of Singapore Chinese New Year’s film. Disney+, a streaming media platform owned by Disney, an American film and television group, announced that it had purchased the film and sold its online rights to more than a dozen countries and regions such as China, Hong Kong, China, Macau, China, Taiwan Province, Singapore, Malaysia, Indonesia, Thailand and Vietnam.

The box office performance of the whole schedule was equally excellent. The Biography of Dragon in Qiao Feng set a new record for the PVOD mode, and the box office of King of Sniper: Assassination, Looking Up and Seeing Happy, and Farewell to Tiantuan 2 in Northeast China all broke through 10 million, surpassing the number of online movies in the Spring Festival in 2022 and 2021.

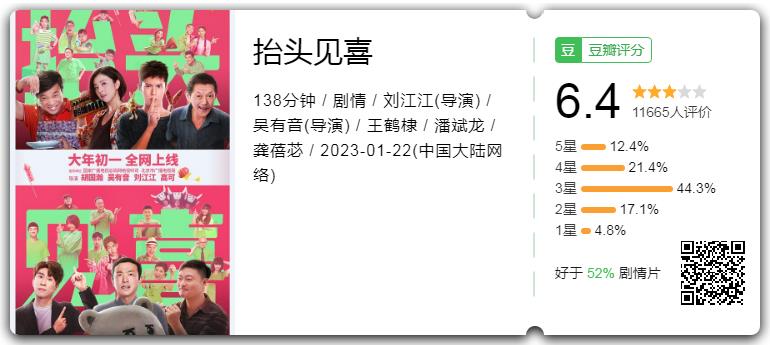

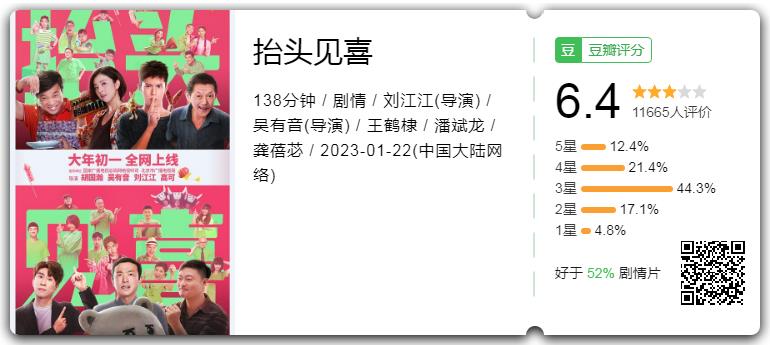

In terms of word-of-mouth and popularity, "Looking Up and Seeing Happiness" scored 6.4 on Douban, ranking TOP1 in the online movie rating of the Spring Festival. As of February 1, it has accumulated 103 hot search topics in Weibo, Tik Tok and Aauto Quicker, making it the most popular movie in the online movie during the Spring Festival this year.

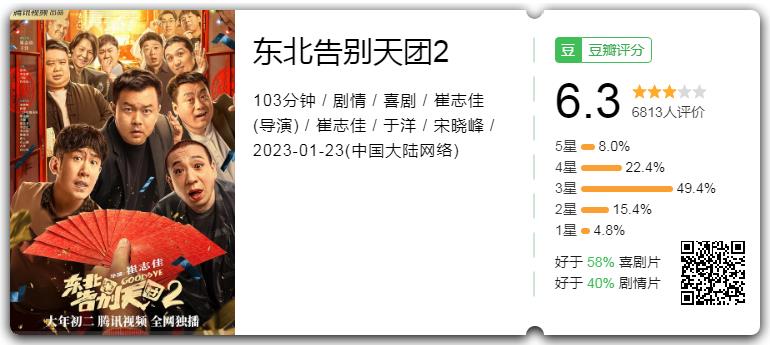

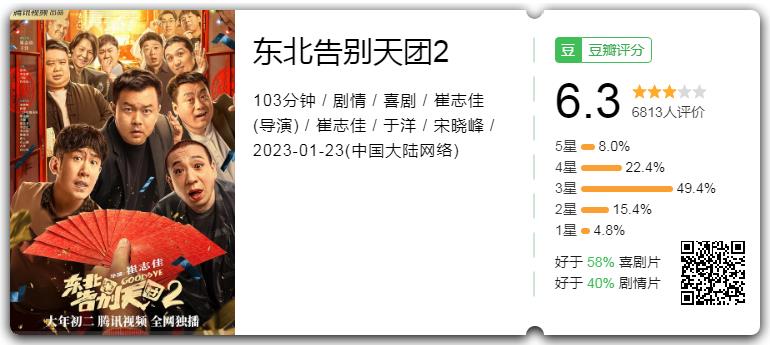

Northeast Farewell to Tiantuan 2 is the comedy with the highest score of Douban in the Spring Festival. At present, Douban scores 6.3, which is higher than the previous series. Two high-quality comedies have helped to create a new high reputation for online movies in the Spring Festival in the past three years.

Action and comedy IP dominate.

Action films and comedies occupy a dominant position in this year’s online movie Spring Festival, and become the two main forces supporting the whole schedule.

On the one hand, there is a lack of pure action movies in this year’s Spring Festival cinema, and the appearance of the martial arts action movie The Legend of Qiao Feng and the modern action movie The King of Sniper: Assassination has met the needs and expectations of action-loving audiences. On the other hand, comedies are in line with the festive atmosphere of the Chinese New Year, and they are the first choice for most audiences.

Martial arts novels are one of the key development contents in the current online movie market. Last New Year’s Eve, the Jing Wong version took the lead to create a high box office; This year, Qiao Feng Biography of Dragon and Eight Branches was upgraded in an all-round way, and Jin Yong’s IP fever was renewed.

Donnie Yen said in an interview with 1905 Film Network that he likes Qiao Feng, a martial arts figure with strong charm, so he wants to develop new possibilities through him. "If I don’t take it as a remake of Jin Yong, I might make a new martial arts film, a martial arts film in 2023."

Donnie Yen

Qiao Feng Biography of Dragon and Eight Branches has a strong cast. Apart from being able to play Qiao Feng better, A Zi in Liu Yase is different from A Zi’s unruly waywardness in the past, and Ruan Xingzhu in Kara Wai is also different from the previous "silly elder sister" personality. These powerful actors have reshaped Jin Yong’s martial arts role, bringing a different flavor.

The sniper-themed "King of Snipers: Assassination" quickly broke through 10 million in five days, and currently ranks as the single-chip box office champion of this Spring Festival with over 16 million box office. This film revolves around the story of female snipers fighting drug lords, and this achievement also represents the rise of the new IP of military action movies.

As well as the special for the Spring Festival, have become two popular comedy series in online movies.

"I like happy reunion, and I like to make me laugh and make me a beautiful movie." The leading actor of "God of Wealth 4" said that they hope to bring laughter to the audience and have a happy year with this "not too abstruse and simple movie". This is also the reason why this IP is enduring and continues to be loved by the audience.

Actor xiu Rui

Realistic theme, broaden the expression space

In this busy schedule, comedies not only provide the simple function of making the audience laugh, but also have the observation of real life and the in-depth expression of humanistic feelings. This creative route of combining realism broadens the situation that the online movie market is dominated by genre films for a long time.

The reality comedy "The Great Event" starring takes the prospective father-in-law as the starting point of the story, and pays attention to the phenomenon topic in domestic marriage, which resonates with the audience.

The runaway God of Wealth 4 starring Xiu Rui and Sun Yue conveys a positive attitude towards life, which is warm and funny, with a fantasy story of a young man who suddenly meets God of Wealth in his dream, modifies his fate and finds himself again.

"Looking Up and Seeing Happiness" is particularly special, and consists of four unit chapters. This kind of family comedy also focuses on hot topics such as middle-aged crisis, family responsibility, care for the elderly, and children’s education. The director believes that "compressing the perspective and shooting the stories around those very small and delicate people may be a road to promotion for online movies."

Among them, "Looking Up and Seeing the Happy Second Treasure Rescue War" is inspired by the director’s own parenting experience. After "Important Events in Life", the director once again takes family as the cutting-in perspective, telling the story that Dabao’s niece opposed the second treasure foster care and fought bravely with her elders to "win" her younger brother back.

"We have set up several different family states, including two-child families, elderly people with babies, stay-at-home mothers and dads, as well as adult sisters and younger brothers, and children’s sisters and younger brothers. The visibility is very full, and it is also an interesting story with laughter and tears." Liu Jiangjiang said.

Director Liu Jiangjiang

"Grandfather who looked up and saw happiness bravely entered the meta-universe" is also based on the family of director Hu Guohan and his relationship with his grandfather, and tells the warm story that his grandson used meta-universe technology to let his grandfather and his late grandmother meet again.

Hu Guohan once directed "Tough Gun God" and "Dream on! Jingjing, Forensic Medicine Song Ci and other different types of works, The Tough Gun God, which scored 7 points in Douban and was popular at the box office, was a phenomenal work of that year, which improved the quality of online movie action movies. This is the first time to try a comedy film. He thinks that more breakthrough is to tell a family story in this genre, which he has never filmed before.

Director Hu Guohan

This film is also the first time for young actor Dylan to act in a movie, which has brought a lot of traffic and attention. Between the film and the actor, the remarkable effect of mutual addition has been obtained.

Originally, the script was written about the story of old Beijing. Because Dylan was from Sichuan, the director thought of changing the role of grandson to the setting that he grew up in Sichuan and returned to Beijing when he grew up. "He can perform this character more easily, and he can dance two sentences of Sichuan dialect and two sentences of old Beijing dialect appropriately, which also gives this character a thicker display. When he speaks old Beijing dialect, he is lying. When he speaks Sichuan dialect, it means that he is telling the truth. This is an egg. "

Hu Guohan expressed the hope that the audience can pay more attention to the psychological state of the elderly around them through this film, find their own position again through "lying flat" grandchildren, and regain the story of loving their careers, and also hope to inspire the young people at present.

tag

Throughout the Spring Festival of online movies in 2023, box office, word-of-mouth, genre, theme, expression and other aspects have made breakthroughs, and various platforms have continuously upgraded their broadcasting operations and marketing promotion.

During the Chinese New Year, a number of creative live connections were linked to promote the popularity of films, and combined with the interesting content of each film, exclusive barrage special effects were launched to attract audience interaction. In addition, we also cooperated with some cinemas and lifestyle apps to promote online movies to offline scenes and expand the audience range of films.

No matter how to play the propaganda strategy, high-quality content quality is still the core demand of the audience. Entering the third year, the online movie Spring Festival file has ended in a more mature state. The online movie market in the new year is still promising, and we look forward to it together.